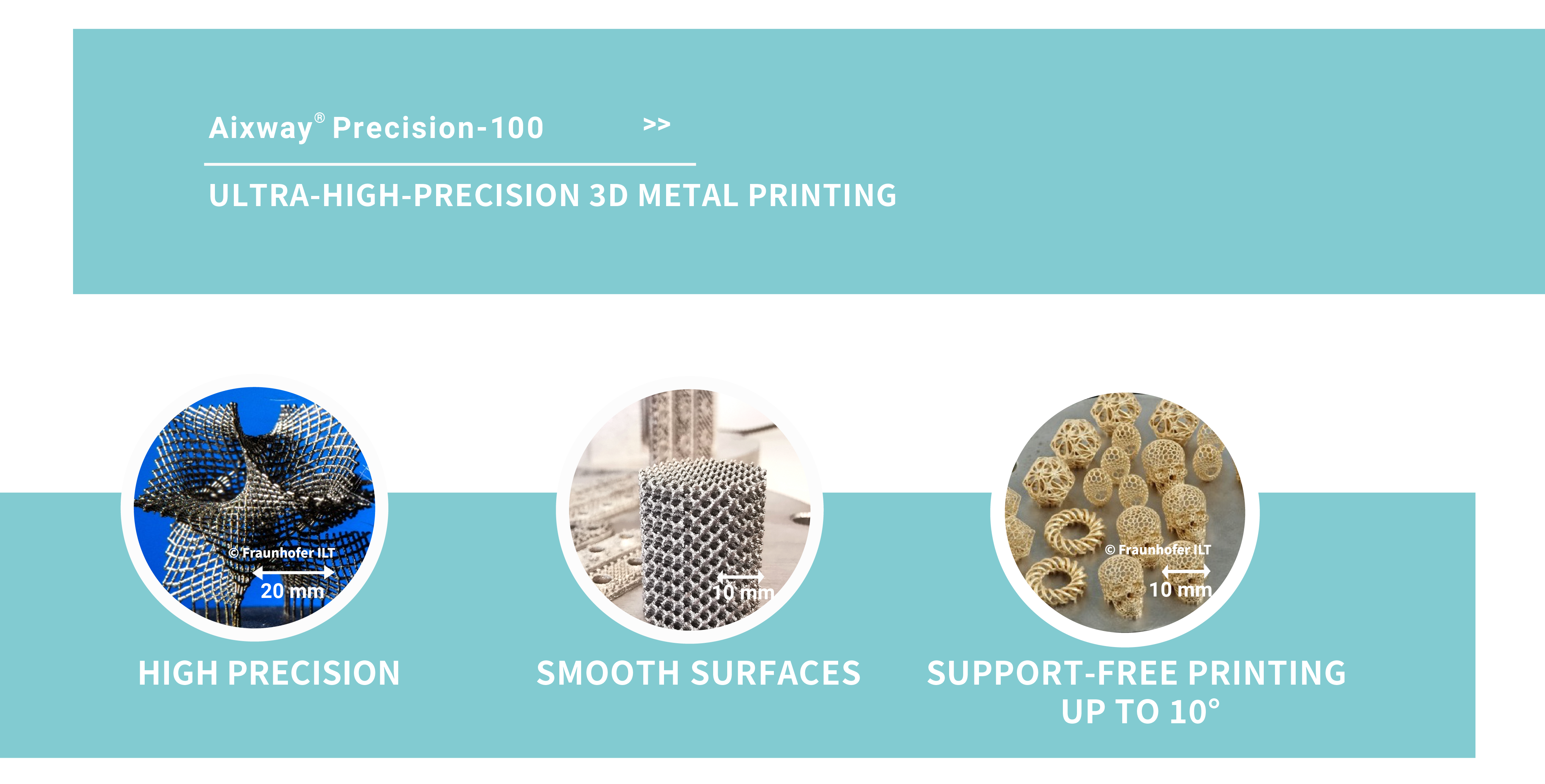

Aixway® Precision-100 uses ultra-fine metal powder, combined with special feeding technology,

to enable high-precision 3D printing with different materials.

Ultra-high forming accuracy

Ultra-low surface roughness

Ultra-complex structural precision

Support-free printing up to 10° overhang

Replaceable feeding and process cylinder with our Easy-Access System